Module Embedding

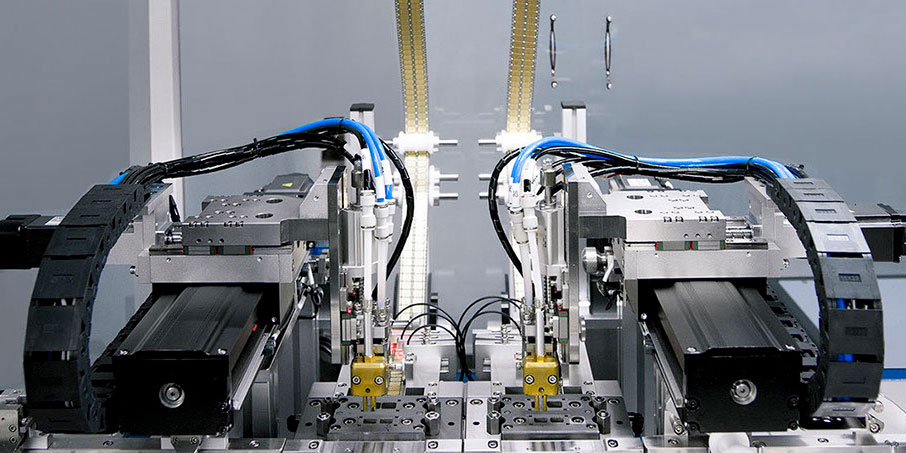

Module embedding is the process of adding a smart chip, either memory or micro-controller, to a plastic card by milling a profile into the card and bonding the module in place. Our automated solution can produce many thousands of cards per day from our Technical Centre.

Our experienced bureau team have multiple years of experience in producing cards and the ISO testing that is needed to ensure compatibility with all major brands of reader technology. We utilise specialist testing equipment to continuously check products as well as conduct a full visual and electronic verification of every card.

Working with Infineon Technologies AG, a leading global silicon manufacturer, we have developed a solution to manufacture dual interface micro-controller chip cards that can be used in many solutions such as payment, authentication, certification, healthcare, biometrics and government ID.

This innovative technology allows us to hold chip modules in stock and create card bodies on demand. Lead times for finished dual interface microcontroller cards can be as low as 4 weeks, which is extremely fast when compared to the usual 12-16 weeks from most other card manufacturers. We are also able to offer lower minimum order quantities values using this technology.

Our module embedding line is part of our bureau service for personalisation, encoding & fulfilment located at our Technical Centre in Portsmouth. Cards that we have manufactured are in use all over the world, in many leading card solutions that you may already be familiar with.

To learn more about this and other services we can offer call us today on 0333 700 0078 or email sales@usmartcards.com